EMI Noise Suppression

What is EMC?

EMC: Electromagnetic Compatibility

Electromagnetic compatibility (EMC) is the suppression of unwanted noise.

Why is electromagnetic compatibility important?

Electromagnetic waves are sometimes very useful for communication means, but they can also cause problems if they interfere with other devices. Transversely, many digital devices work off of many different frequencies, however sometimes these can also interfere with RF communications. Each country has regulating laws for EMC, and some even prohibit devices with excessive wave emissions from being imported or sold. Due to this, electronic manufactures face the necessity of suppressing EMI. In our current life style, it is impossible to avoid electromagnetic energy and therefore, we need to live with them as a norm.

Noise Suppression Method

There are two main EMC problems:

EMI Grounding

A large area of ground is better for ensuring the reference voltage. For this reason, multi-layer PCBs often designate a layer for grounding, or a metal frame is installed. Another important point is how to connect a ground to another: the wider the plane and shorter the distance, the better.

Connecting the PCB ground to a metal frame is called frame ground. This is a common practice. The effectiveness depends on how short the distance between the contacts are and how many grounding points are connected.

EMI Filtering

High harmonic noise from a clock signal on a digital circuit and switching noise that occurs on the control circuit tend to travel via circuits and cables in the form of radiating Common Mode noise. On the other hand, the signals that should be travelling through the device are transmitted as Differential Mode noise. Ferrite cores and Common Mode choke coils can be used to block Common Mode noise so that only the Differential Mode signals can pass through, in effect filtering the signal from unwanted noise.

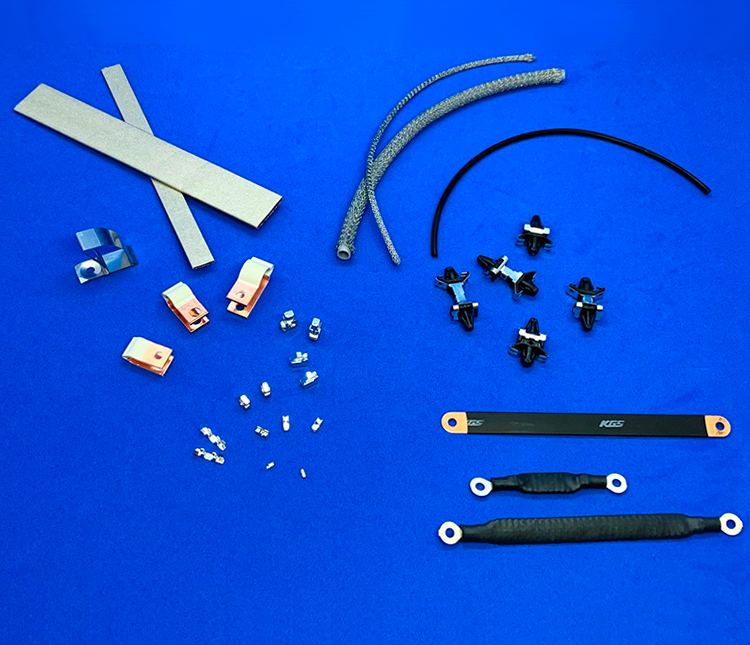

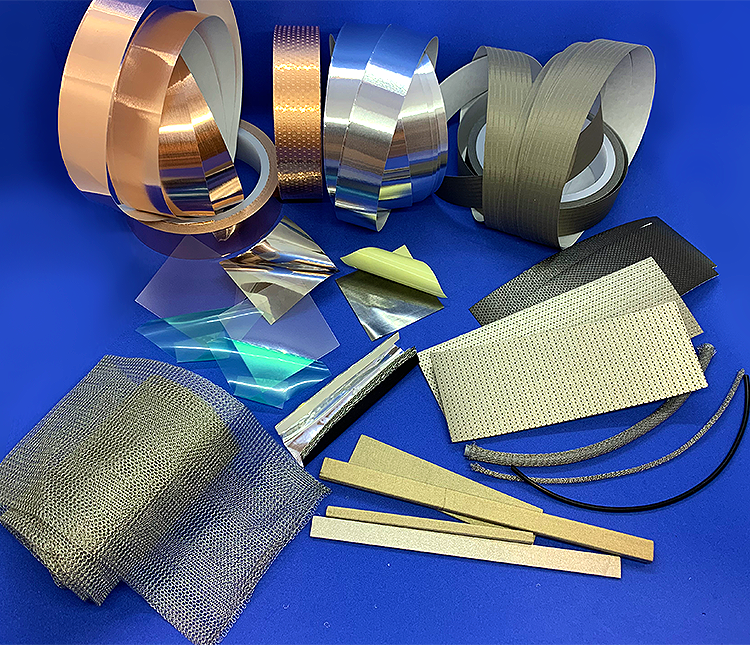

EMI Shielding

The shielding method involves covering a part of the circuit or the entire device with metal screening material where noise is radiating. This traps the noise inside and prevents it from emitting outside the shield. At the same time, shielding blocks the noise entering from outside, which, as a result, protects the circuit’s function from being affected by outside noise (immunity). Both emission suppression and immunity are the properties of shielding, but in order to optimize the effectiveness, it is important to carefully design the layout to prevent the leakage of magnetic waves in both directions. For example, the joints of metal chassis, the openings, and the vent holes need to be sealed. Shielding of the cables needs to be grounded to the chassis. It is common to use conductive gaskets, tapes and metal mesh, as well as conductive cable shielding jackets and conductive grounding clamps for this purpose.