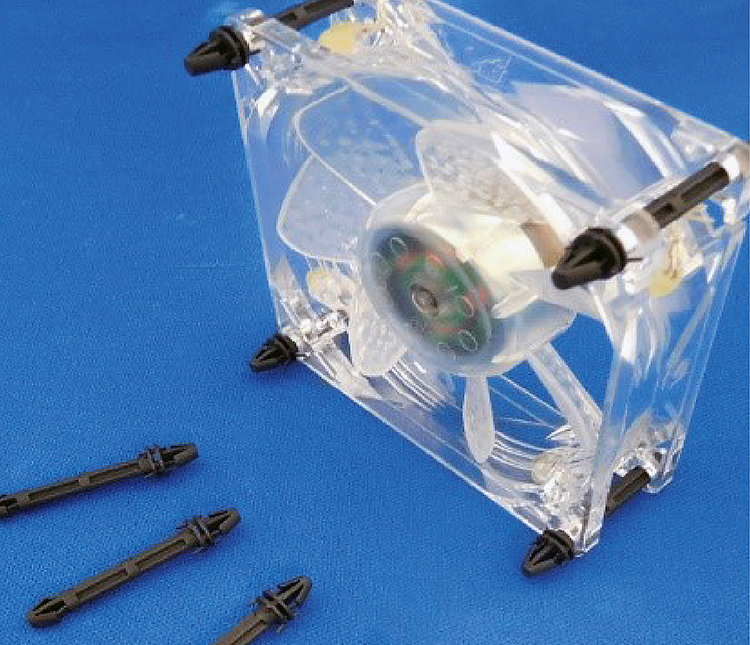

We are global solutions provider of EMC, thermal, vibration, and plastic parts

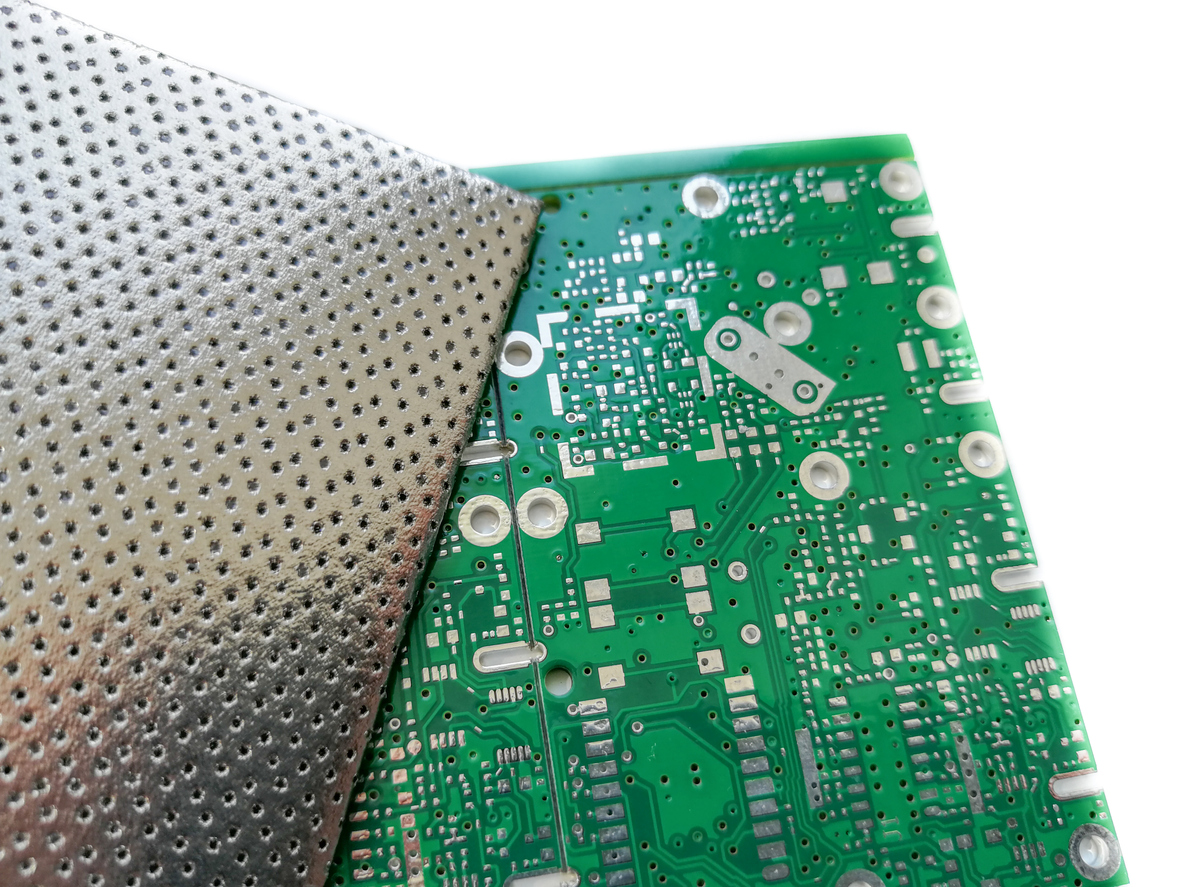

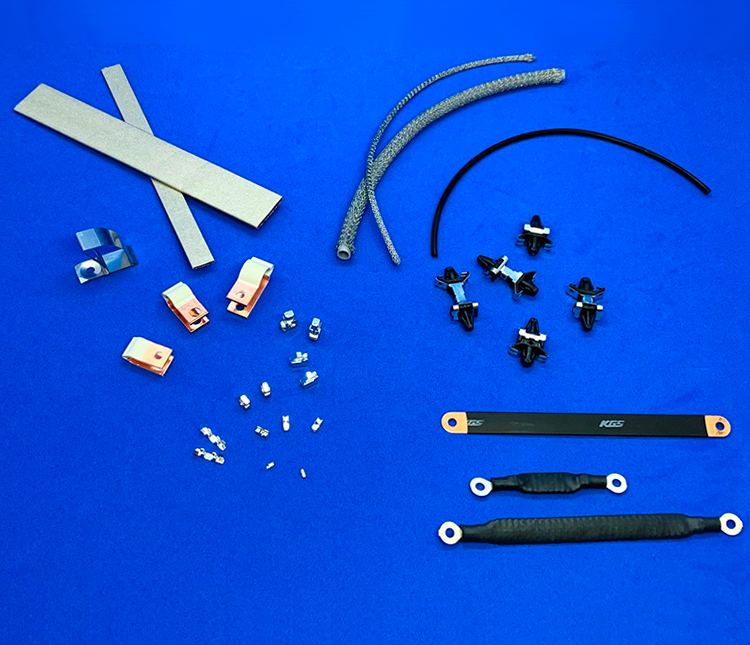

KITAGAWA INDUSTRIES America offers a broad range of the most advanced and sophisticated EMI/RFI shielding components. These products are designed to provide solutions to all EMI/RFI and ESD requirements.

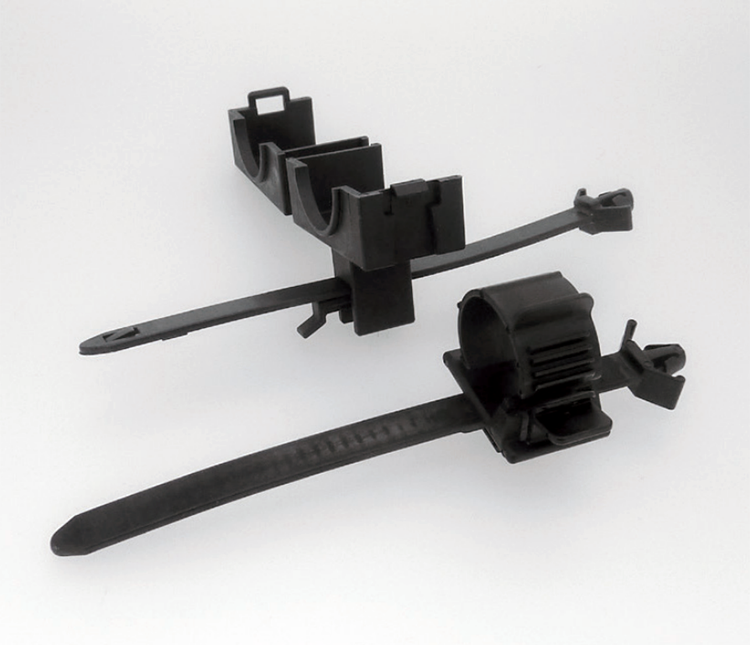

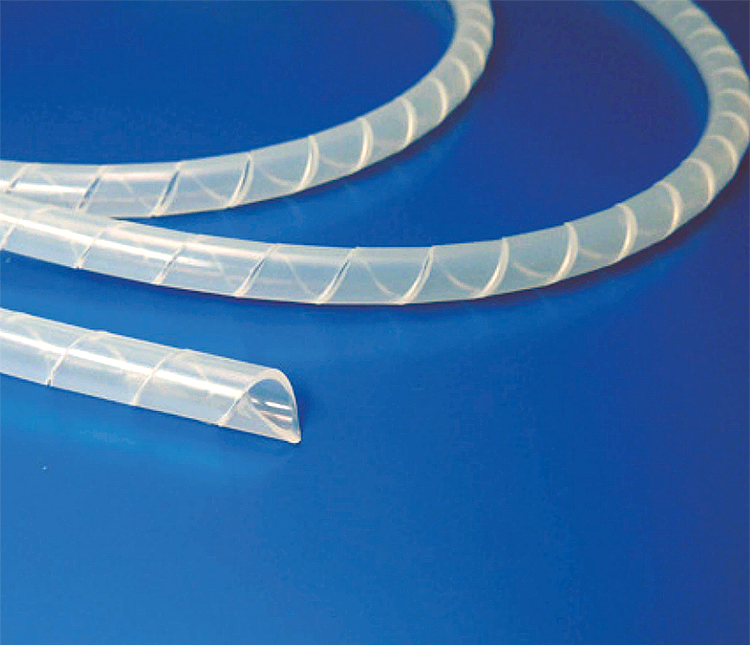

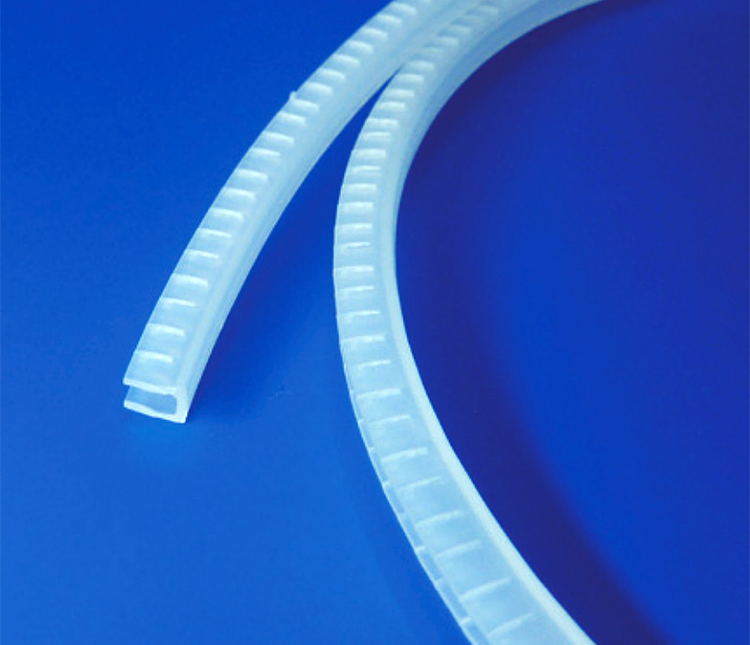

The product lines comprise a wide range of ferrite products for the EMI suppression, cable shielding materials, grounding fasteners and conductive gaskets. Other product line segments include a complete selection of plastic fasteners and hardware for the electronic packaging, optical fiber inspection equipment and thermal management components.

Many of the KITAGAWA INDUSTRIES America products in the EMI/ESD range are unique in terms of technical characteristics and quality and were introduced on the market by KG, who registered international patents for these original parts.

Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) concerns both unintended electromagnetic emission from an electronic equipment as well as the ability of an equipment to function in the presence of electromagnetic interference (immunity).

KGS’ iNARTE certified engineers are ready to help you find the best solution for your project.

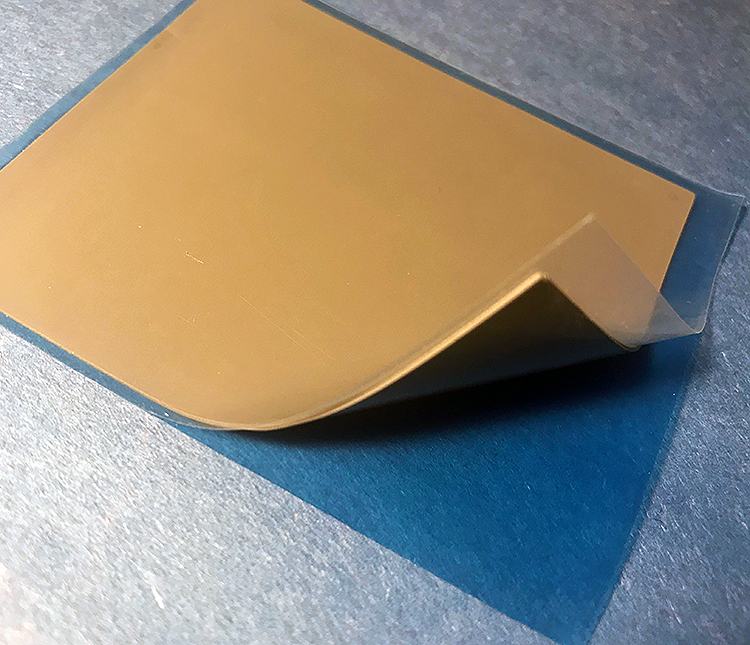

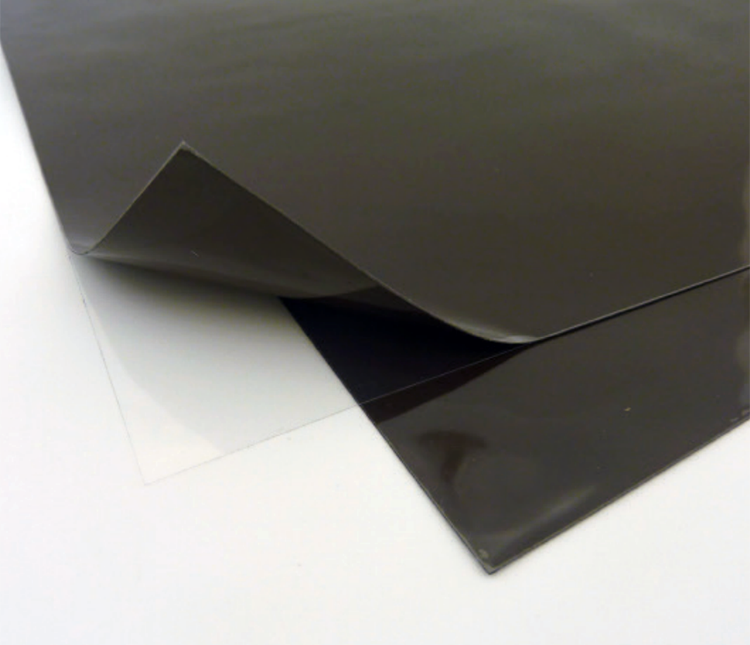

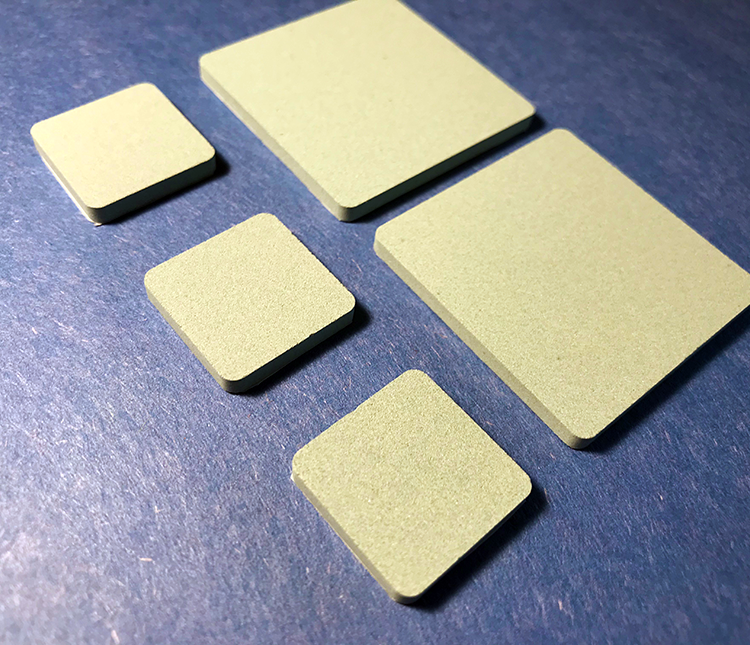

Thermal Pad

(Thermal Interface Materials)

KITAGAWA INDUSTRIES America’s thermal products come in a variety of different types and sizes. They come in a large range of thermal conductivities from 1.0 W/m*K up to 7.0 W/m*K. Thicknesses are also flexible from 0.25 mm and up. They also use different materials depending on the application’s requirements such as silicone and acrylic rubber. They are available with both sides being self-tacky or one side-tacky. Finally, die cutting is an option available upon request.

Thermal Pad (Thermal Interface Material) is used in a variety of electronic applications and industries including computers, laptops, tablet PCs, smart phones, routers, LEDs, solar, medical device, power supplies, wireless devices, and the automotive industry.

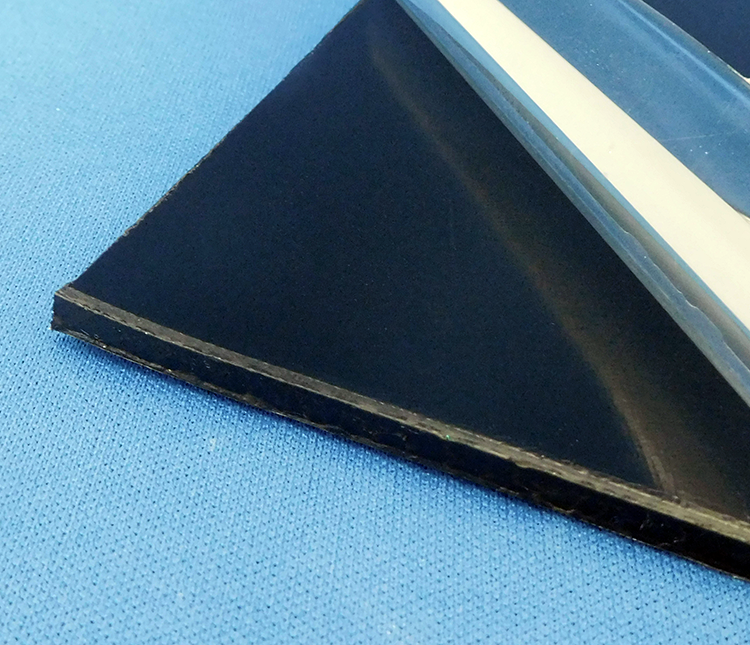

Vibration Damping Materials

Notebook computers, PDAs, car navigation systems, mobile phones, and many other types of electronic equipment are subject to vibration from internal, as well as external sources, such as accidental dropping.

Vibration damping is a crucial requirement for most electronic systems. Vibration is a main source of damage to electronic components and connections. Without adequate vibration damping many, soldered connections can become weakened or severed, connection signals can be diminished and components can be broken beyond repair.