Thermal Putty: CPVG Series

Silicone-free, single-liquid, no-drip thermal putty

Properties

*Under development

| Part Number | CPVG-30 | CPVG-50* |

|---|---|---|

| Thermal Conductivity (W/m•K) *ISO22007-2 Hot-disc method | 3.0 | 5.0 |

| Thermal Resistance t1.0mm (°C/W) *ASTM D5470 | 0.33 | 0.19 |

| Thermal Resistance t0.3mm (°C/W) *ASTM D5470 | 0.08 | 0.05 |

| Thermal Resistance t0.1mm (°C/W) *ASTM D5470 | 0.01 | 0.00 |

| Color | Gray | Blue |

| Specific Gravity *JIS Z 8807 | 2.9 | 3.2 |

| Viscosity 0.5 [1/s] (Pa•s) *ASTM D1824 Compliant | 3,300 | 6,500 |

| Viscosity 1.0 [1/s] (Pa•s) *ASTM D1824 Compliant | 2,500 | 4,000 |

| Volume Resistivity (Ω•cm) *JIS K 6911 Compliant | 1.0 x 10⁹ | |

| Breakdown Voltage (kV/mm) *JIS K 6911 Compliant | 8 | 12 |

| Relative Permitivity 500MHz *Company Standard | 8.98 | 13.47 |

| Relative Permitivity 1GHz *Company Standard | 8.88 | 13.58 |

| Flame Resistance | UL94 V-0 equivalent | |

| Operating Temperature (°C) | -40 ~ 125 | |

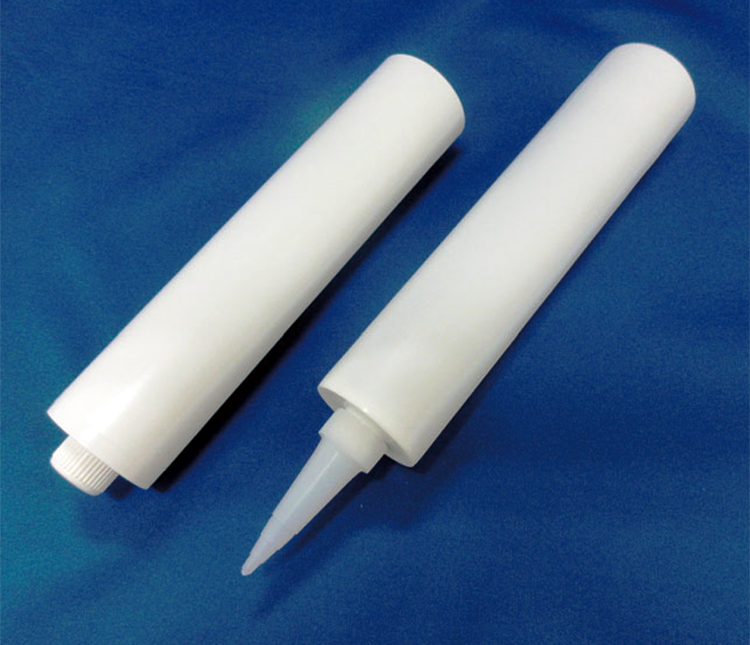

| Product form when supplied | Cartridge: 330ml | |

*TEST METHOD

Results Of Drip Off Test

Dripped Off

No-drip Off

No-drip Off

Test Conditions:

Temperature: 125 °C

Time: 1000h

Coating thickness: t=1mm

Material: Glass + Aluminum plate

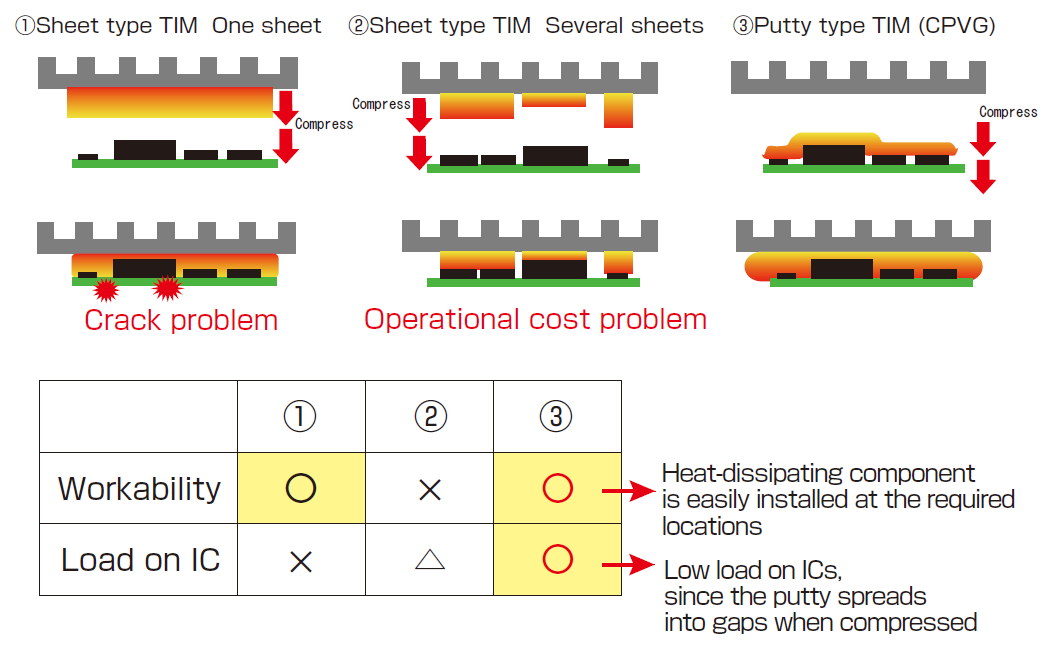

Workability of CPVG (Putty TIM) and the load on ICs

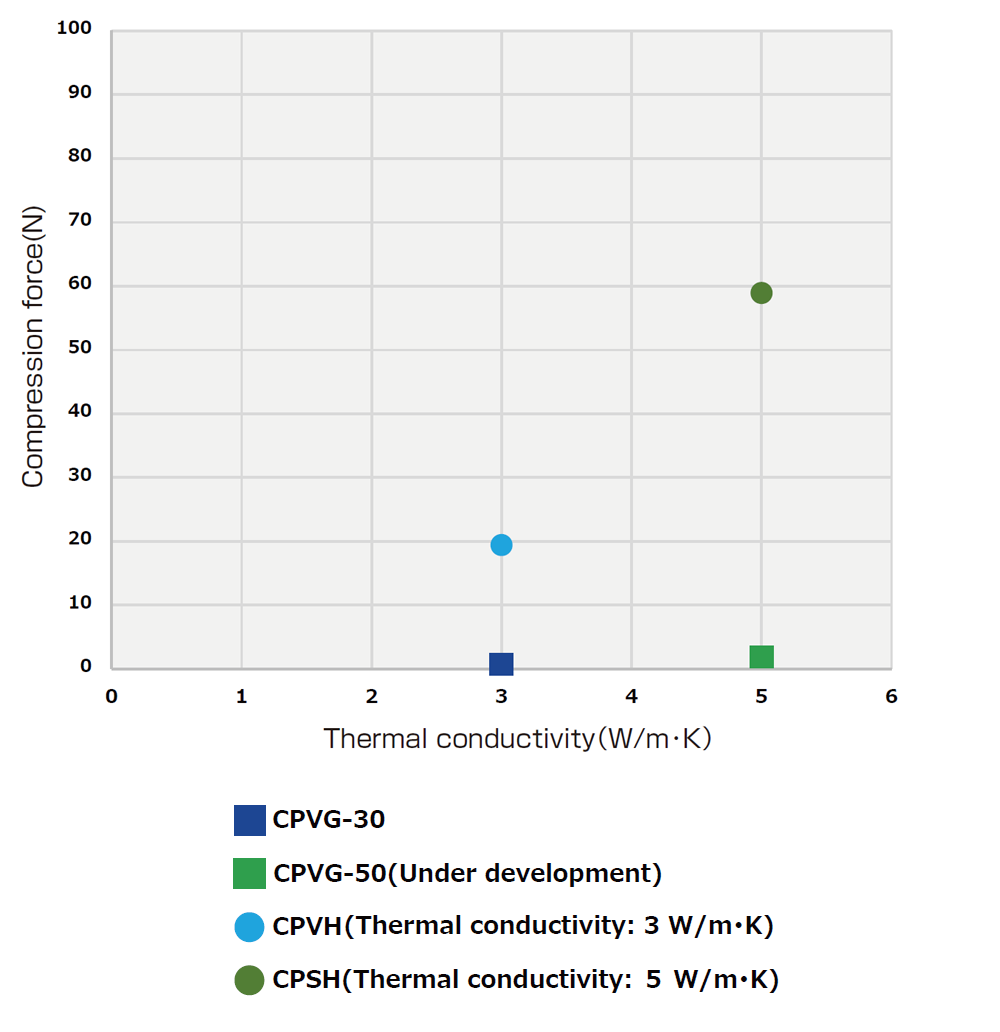

Compressive force and thermal conductivity

Comparison with sheet TIMs

* Specifications and dimensions are subject to change without notice for product improvement.