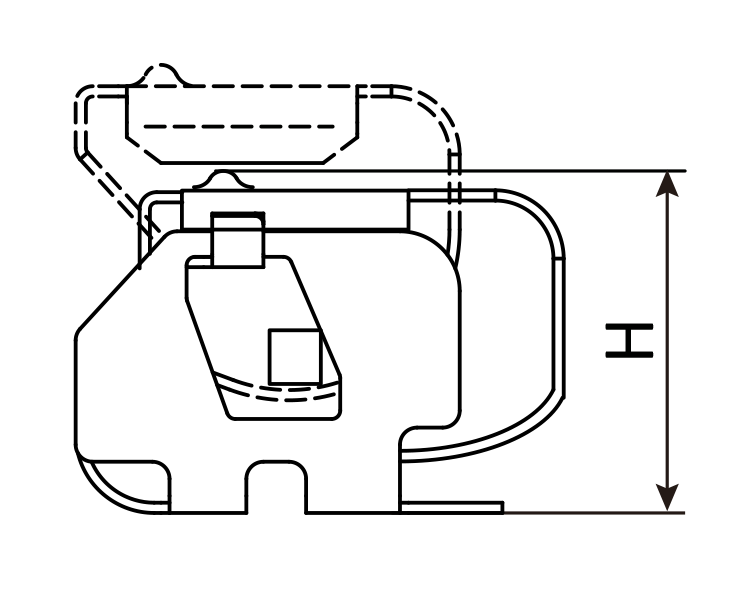

On‐board Contact for Parallel EMC Grounding: OG-503253-A

SMT grounding contact for engine compartment PCB.

| Part No. | OG‐503253‐A |

|---|---|

| Applications |

[/fusion_text]Ground clip for SMD |

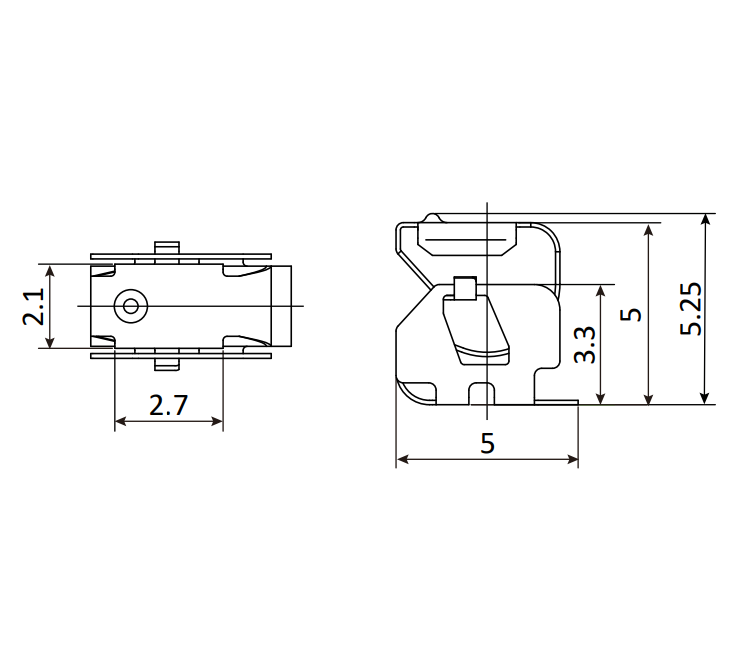

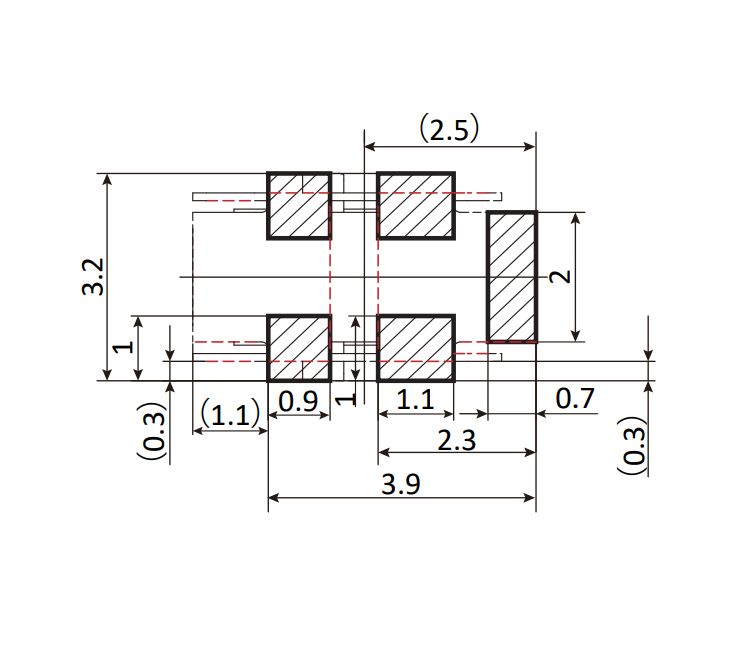

| Length | 5.0 mm |

| Width | 3.2 mm |

| Height* | 5.25 mm |

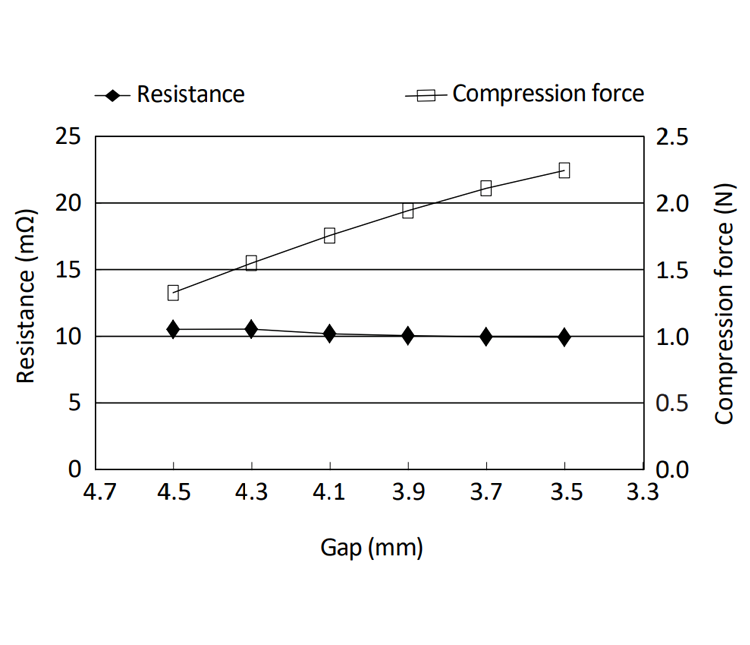

| Recommended Gap | 3.5 ~ 4.5 mm |

| Base Material | Beryllium Copper |

| Surface Treatment | Sn plating, Cu undercoat |

| Qty per Reel | 2,000 pcs |

| Operating Temperature | ‐40 ~ 150 °C |

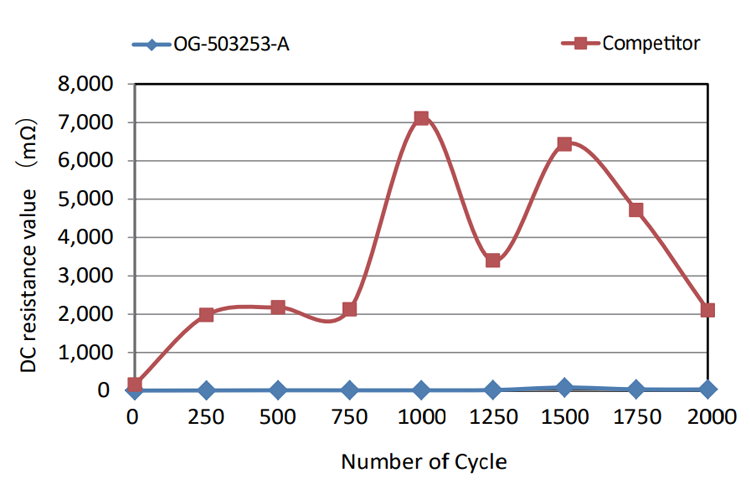

* Dimple included on the top surface of OG‐503253‐A to maintain metal‐to‐metal connection during vibration.

* Specifications and dimensions are subject to change without notice for product improvement.