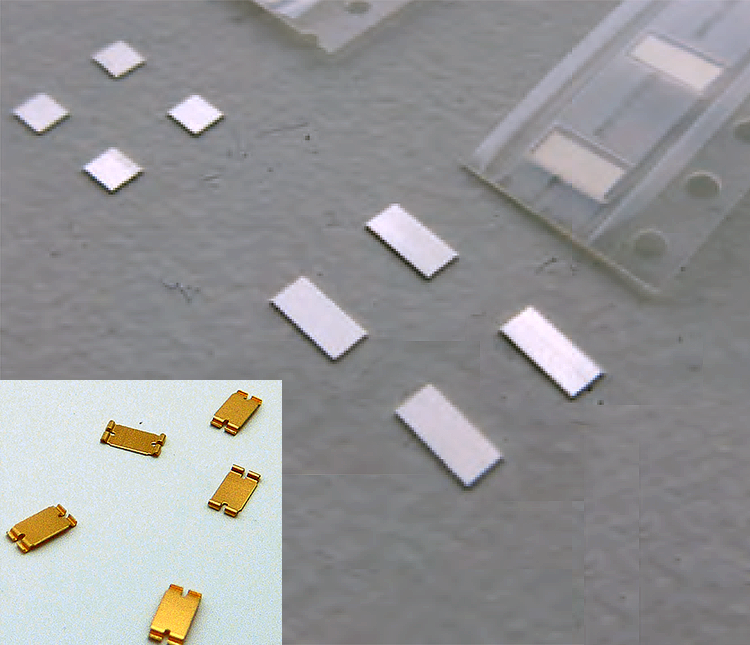

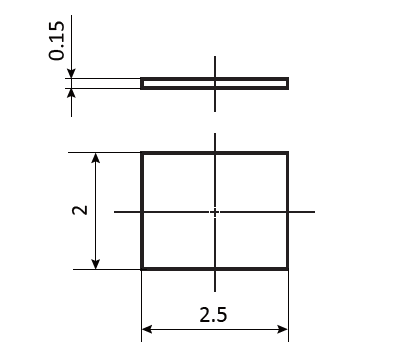

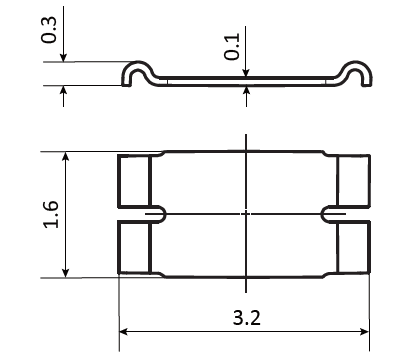

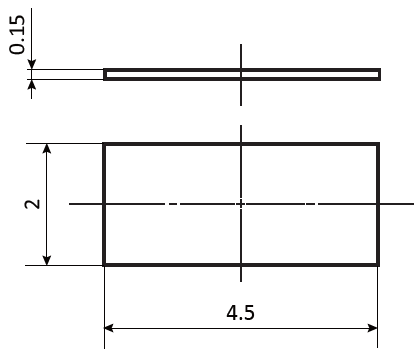

Onboard Plate: OGP-2520, OGP-3216, OGP-4520

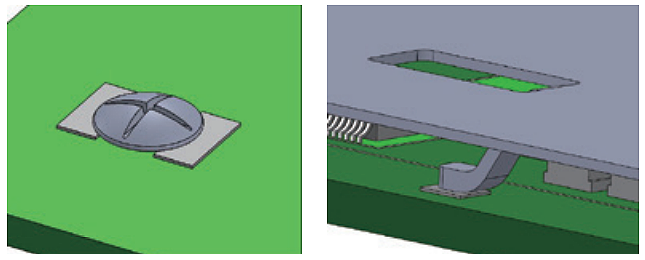

OGP configuration ensures reliable contact.

Material

Base material: Brass

Surface treatment: Sn reflow plating ※(First plating: Cu plating)

※Surface treatment for OGP-3216: Au/Ni plating on both sides.

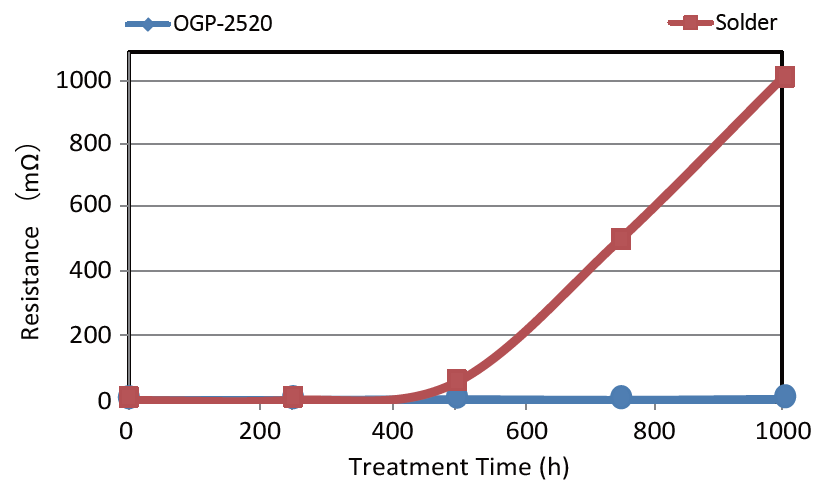

Resistance Measurement Results

Test method:

1: A terminal and OGP-2520s are soldered on a substrate. A second terminal is soldered on to a separate substrate, with solder fillets applied on the substrate at the same position as the OGP.

2: A screw is tightened in each location and the substrates are heat treated.

3: After the treatment, the resistance between the terminal and screw is measured with a Milliohm HiTester.

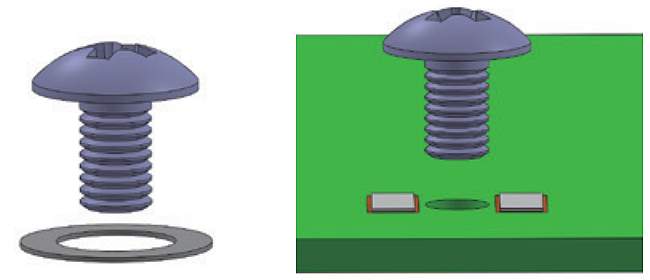

Application Examples

| Washers | OGP Series | |

|---|---|---|

| Mounting Method | Manual | Automated |

- Cost saving by automa?on!

- Parts are automatically counted by mounters.

* Specifications and dimensions are subject to change without notice for product improvement.